Computer vision for quality assurance can be found most often in automotive manufacturing (engine blocks, paint finish, door sheets), computer chips and wafers, batteries, solar panels, and more. Visual inspection is typically performed in-situ as the manufacturing process is being performed, utilizing sensors like high-speed cameras or spectrometers that, when combined with the machine learning algorithms, can detect errors and defects with high degrees of accuracy.

“AI is typically excellent for quantitative tasks, such as the ones traditionally performed by humans—locating and identifying defects such as surface scratches, missing or damaged PCB components, dust particles on an image sensor,” Ménard said.

Here are some of the most prominent examples of companies using computer vision and artificial intelligence for quality assurance:

Welding seams: To inspect welds, the artificial intelligence model is trained on what kinds of irregularities the algorithm should identify as errors, such as splatter or if the seam has collapsed during welding. Automotive manufacturers use visual inspection to inspect robot-welded seams for anomalies at critical structural joints on the chassis.

Automobile parts: Visual inspection is used in a variety of cases in quality assurance in automobile manufacturing. For instance,

Renault uses Google Cloud’s Visual Inspection AI to implement more accurate quality controls with a significantly reduced time to market at a lower cost. And Ford is using the same tool to look for defects at the stamping station for metal sheets in its cars.

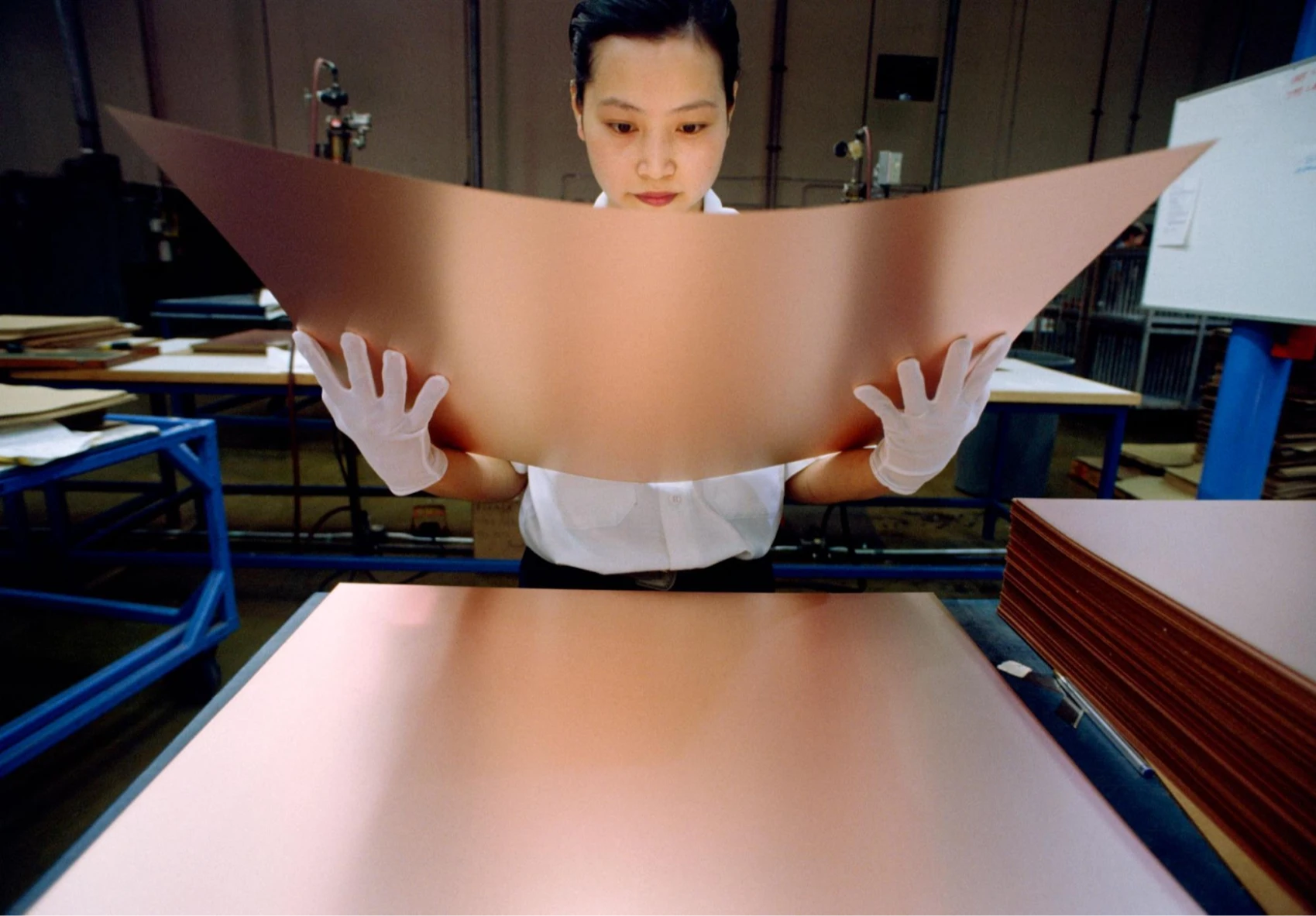

Lithium-ion battery sheets: Lithium batteries of all sizes are made of positively charged sheets (cathodes), negatively charged sheets (anodes) and a separator sheet placed between them with a liquid or solid electrolyte layer to facilitate connections between the sheet. While the concept of lithium-ion batteries is simple, the manufacture can be sensitive. Line scan cameras are mounted in the production facility to inspect the sheets as they move quickly by, looking for surface defects like scratches, dents or bent edges.

Traditional inspections could often be tedious, and misses were more common.

Traditional inspections could often be tedious, and misses were more common.

Workers remain essential to visual inspections, and are now empowered to perform more high-value tasks.

Workers remain essential to visual inspections, and are now empowered to perform more high-value tasks.